Technology

HDDs record data by magnetizing ferromagnetic material directionally, to represent either a 0 or a 1 binary digit. They read the data back by detecting the magnetization of the material. A typical HDD design consists of a spindle which holds one or more flat circular disks called platters, onto which the data are recorded. The platters are made from a non-magnetic material, usually aluminum alloy or glass, and are coated with a thin layer of magnetic material. Older disks used iron(III) oxide as the magnetic material, but current disks use a cobalt-based alloy.[citation needed]

The platters are spun at very high speeds. Information is written to a platter as it rotates past devices called read-and-write heads that operate very close (tens of nanometers in new drives) over the magnetic surface. The read-and-write head is used to detect and modify the magnetization of the material immediately under it. There is one head for each magnetic platter surface on the spindle, mounted on a common arm. An actuator arm (or access arm) moves the heads on an arc (roughly radially) across the platters as they spin, allowing each head to access almost the entire surface of the platter as it spins. The arm is moved using a voice coil actuator or in some older designs a stepper motor.

Older drives read the data on the platter by sensing the rate of change of the magnetism in the head; these heads had small coils, and worked (in principle) much like magnetic-tape playback heads, although not in contact with the recording surface. As data density increased, read heads using magnetoresistance (MR) came into use; the electrical resistance of the head changed according to the strength of the magnetism from the platter. Later development made use of spintronics; in these heads, the magnetoresistive effect was much greater than in earlier types, and was dubbed "giant" magnetoresistance (GMR). This refers to the degree of effect, not the physical size, of the head — the heads themselves are extremely tiny, and are too small to be seen without a microscope. GMR read heads are now commonplace.[citation needed]

HD heads are kept from contacting the platter surface by the air that is extremely close to the platter; that air moves at, or close to, the platter speed.[citation needed] The record and playback head are mounted on a block called a slider, and the surface next to the platter is shaped to keep it just barely out of contact. It's a type of air bearing.

The magnetic surface of each platter is conceptually divided into many small sub-micrometre-sized magnetic regions, each of which is used to encode a single binary unit of information. In today's HDDs, each of these magnetic regions is composed of a few hundred magnetic grains. Each magnetic region forms a magnetic dipole which generates a highly localized magnetic field nearby. The write head magnetizes a region by generating a strong local magnetic field. Early HDDs used an electromagnet both to generate this field and to read the data by using electromagnetic induction. Later versions of inductive heads included metal in Gap (MIG) heads and thin film heads. In today's heads, the read and write elements are separate, but in close proximity, on the head portion of an actuator arm. The read element is typically magneto-resistive while the write element is typically thin-film inductive.[6]

In modern drives, the small size of the magnetic regions creates the danger that their magnetic state might be lost because of thermal effects. To counter this, the platters are coated with two parallel magnetic layers, separated by a 3-atom-thick layer of the non-magnetic element ruthenium, and the two layers are magnetized in opposite orientation, thus reinforcing each other.[7] Another technology used to overcome thermal effects to allow greater recording densities is perpendicular recording, first shipped in 2005,[8] as of 2007 the technology was used in many HDDs.[9][10][11]

Modern drives also make extensive use of Error Correcting Codes (ECCs), particularly Reed–Solomon error correction. These techniques store extra bits for each block of data that are determined by mathematical formulas. The extra bits allow many errors to be fixed. While these extra bits take up space on the hard drive, they allow higher recording densities to be employed, resulting in much larger storage capacity for user data. [12]

See File System for how operating systems access data on HDDs and other storage devices.

[edit] Architecture

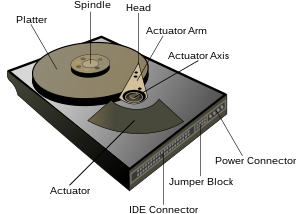

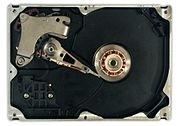

A typical hard drive has two electric motors, one to spin the disks and one to position the read/write head assembly. The disk motor has an external rotor attached to the platters; the stator windings are fixed in place. The actuator has a read-write head under the tip of its very end (near center); a thin printed-circuit cable connects the read-write head to the hub of the actuator. A flexible, somewhat 'U'-shaped, ribbon cable, seen edge-on below and to the left of the actuator arm in the first image and more clearly in the second, continues the connection from the head to the controller board on the opposite side.

The head support arm is very light, but also rigid; in modern drives, acceleration at the head reaches 250 Gs.

The silver-colored structure at the upper left of the first image is the top plate of the permanent-magnet and moving coil motor that swings the heads to the desired position (it is shown removed in the second image). The plate supports a thin neodymium-iron-boron (NIB) high-flux magnet. Beneath this plate is the moving coil, often referred to as the voice coil by analogy to the coil in loudspeakers, which is attached to the actuator hub, and beneath that is a second NIB magnet, mounted on the bottom plate of the motor (some drives only have one magnet).

The voice coil, itself, is shaped rather like an arrowhead, and made of doubly-coated copper magnet wire. The inner layer is insulation, and the outer is thermoplastic, which bonds the coil together after it's wound on a form, making it self-supporting. The portions of the coil along the two sides of the arrowhead (which point to the actuator bearing center) interact with the magnetic field, developing a tangential force that rotates the actuator. Current flowing radially outward along one side of the arrowhead, and radially inward on the other produces the tangential force. (See magnetic field#Force on a charged particle.) If the magnetic field were uniform, each side would generate opposing forces that would cancel each other out. Therefore the surface of the magnet is half N pole, half S pole, with the radial dividing line in the middle, causing the two sides of the coil to see opposite magnetic fields and produce forces that add instead of canceling. Currents along the top and bottom of the coil produce radial forces that do not rotate the head.

Tidak ada komentar:

Posting Komentar